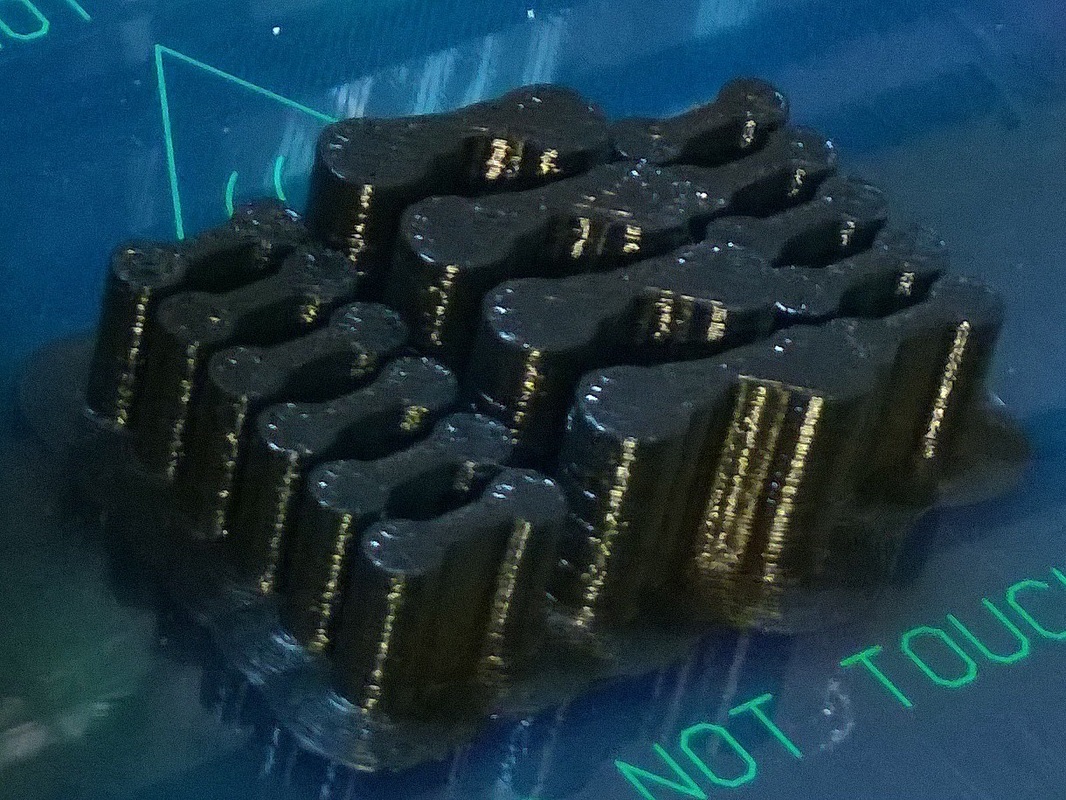

Today I printed the finger joint hinges using my Airwolf3d v5.5 printer. I printed them out of FormFutura Flex EcoPLA. Slicing and printer prep took 10 minutes, the print job itself took 2:22 using a rather slow 30mm/sec print speed. I printed all 15 pieces in a single print job. Since they're small pieces, I printed them with a 5mm brim, to help keep them stuck to the print bed. This worked out really well, and I think these pieces printed a lot cleaner than anything else I've printed with the flexible PLA. The only other notable configuration change with the flexible PLA is a 4mm retract, which is twice what I use with rigid ABS. The flex seems to ooze a bit more than rigid plastic. The extra retraction takes care of this which prevents strings from forming between parts and gives nice clean perimeters. You can find a good description of extruder ooze and how to prevent it, inthis article at www.slic3r.org

Flexy-Hand #Abstract2Actual: 26:52 and counting

Flexy-Hand #Abstract2Actual: 26:52 and counting

RSS Feed

RSS Feed