The A2A 1U CubeSat is representative of the pinnacle of crowdsourced agile engineering.

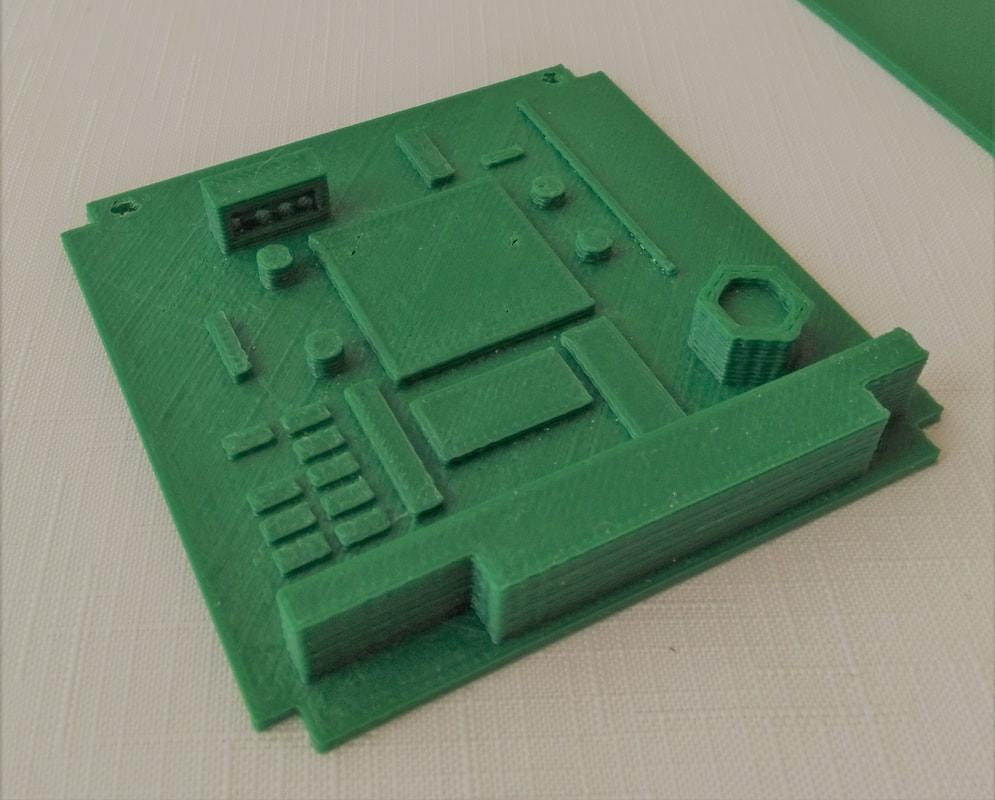

| The Main Board is loosely based on the now defunct open source fractal encabulator. Otherwise, the board is comprised of commercially available off the shelf components including the nofer trunions. Even the most elementary students of encabulation will notice the conspicuous lack of hydrocoptic marzel vanes which, aside from exceeding LFM mass limitations, would be completely useless in the vacuum of space. The sole function of the Main Board is to handle any event of sinusoidal deplaneration. When this occurs, the lunar wayne shaft is engaged to facilitate a forescent score maneuver to prevent bit fumbing. |

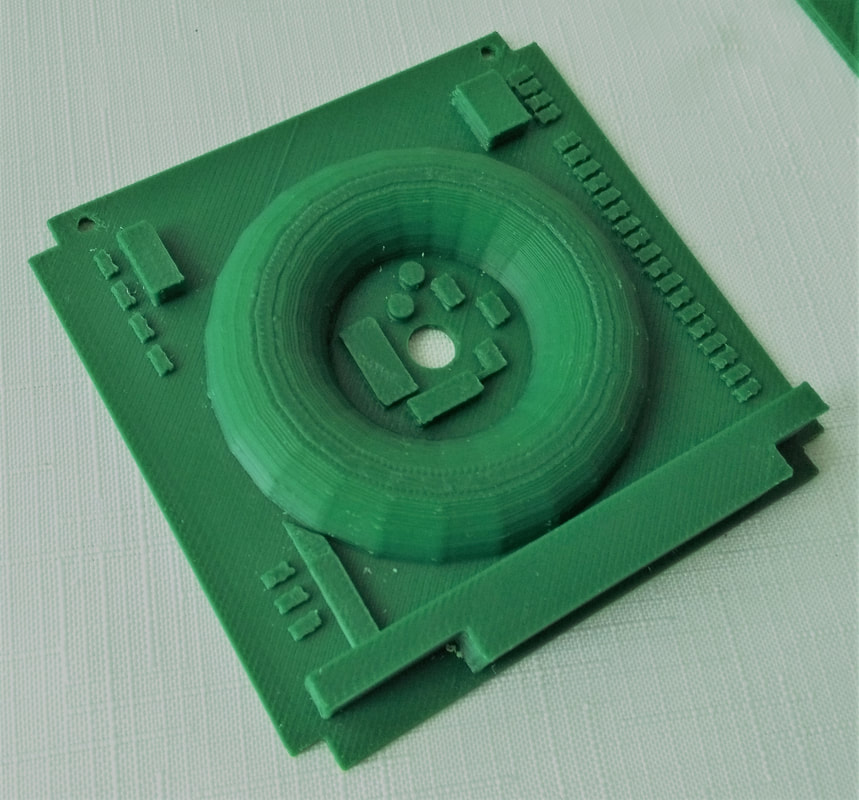

| The micro CERN isometric particle accelerator with tuned ejection port provides primary propulsion at scale. It is capable of producing 6 braleys per terrex in the lateral and longitudinal planes whereas rotationally, the output is a logarithmic tangent of the inverse. A series of concentric ductile plenums conjoined with gribbley collets in an atypical trapezius configuration ensure translational and rotational alignment of particles immediately preceding ejection port engagement. Particle malignancy beyond the distal facia is negligible |

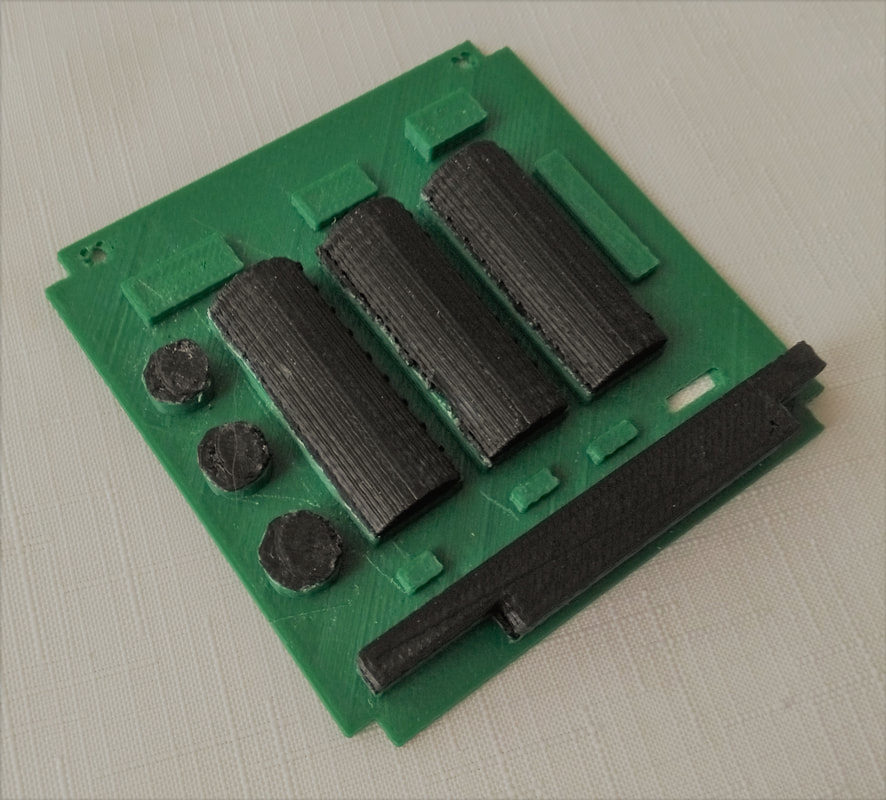

| System power is provided by an advanced quark capture amagulator master power unit (MPU). Bosons passing through the triplet of IEC R6 cells regenerate the cathode through ionization, providing an extended MPU lifespan. Converse redundancy in this configuration, eliminates the requirement for onboard ancillary power units (APUs). |

| I do want to take a moment to thank my good friend Rick Lavin at the Dragon Moonshine Company in Charlotte , NC for first introducing me to the genius of the Encabulator. | |

| | To learn more about the fascinating technology behind the Rockwell International turbo encabulator, check out the youtube video in the link to the left. |

RSS Feed

RSS Feed