I've decided to 3d print a prosthetic hand for a networking event next month. I figured this would be a really cool way to showcase the complexity of what you can do with a 3d printer. I'll keep track of the time I spend on this, which I imagine is going to be a lot.

I'm starting with an open source design Flexy-Hand 2, designed by Steve Wood at Gyrobot Ltd. According to an article on 3Dprint.com, Jeff spent about 20 hours designing the hand. I spent about 2 hours this evening studying the design and figuring out the best way to print it. The files, which are available at Thingiverse.com are already laid out for printing, but there are some overhangs that are going to be a problem with my printer. I added support material, but it ends up being too much support along the sides of some of the phalanges where it really isn't necessary, and will be a beast to get off. So I'm manually tweaking the finger plate a little to include support for those overhangs. Someone probably knows an easier way to configure the support material, and there may be a better slicer program out there for this sort of thing. If you know of anything, let me know. Until I learn a better way, I'll just add some little blocks to support the overhangs.

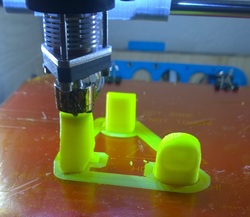

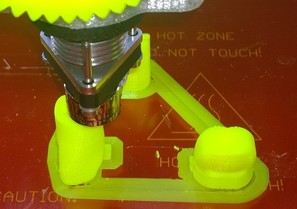

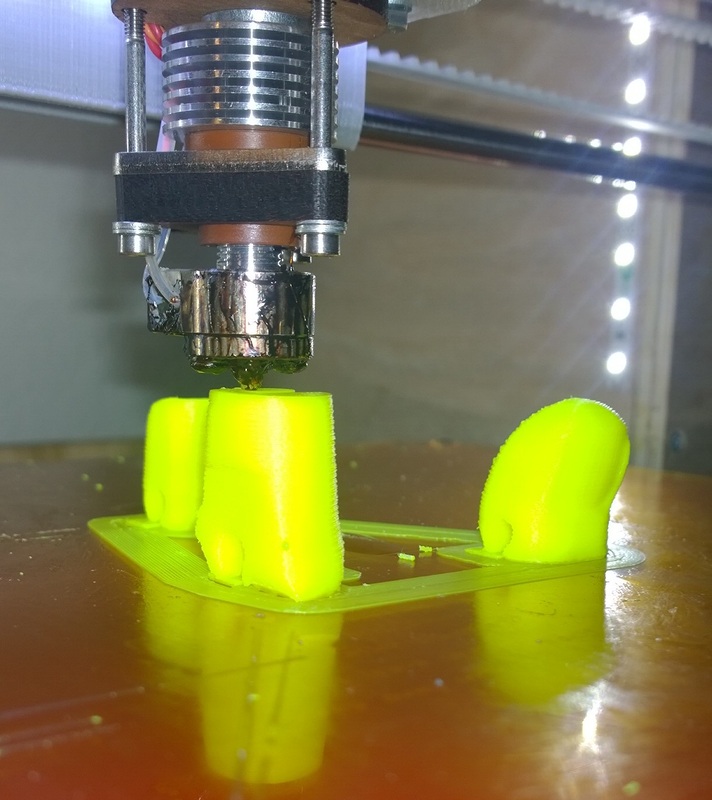

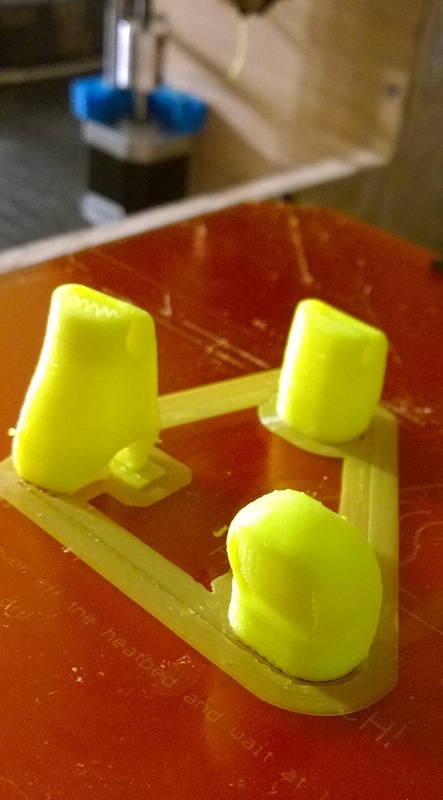

I printed out these three pieces in 3mm yellow ABS to see how my support elements worked. They are too thick and poorly placed, so I'll try again tomorrow. They do look pretty cool though. Ultimately I'm going to print most of the hand out out of 3mm Taulman Bridge nylon. This is a newly formulated nylon that resists curling much better than earlier 3d nylon blends. I'm thinking I'll use flexible PLA which I got from 3Dsupplyworld.com, for the joint material, but I'm not completely set on that yet. Nylon is pretty flexible and I may be able to tweak the filament, density, and wall thicknesses enough to use nylon throughout.

Flexy-Hand #Abstract2Actual: 24:20 and counting (including Jeff's design time)

I'm starting with an open source design Flexy-Hand 2, designed by Steve Wood at Gyrobot Ltd. According to an article on 3Dprint.com, Jeff spent about 20 hours designing the hand. I spent about 2 hours this evening studying the design and figuring out the best way to print it. The files, which are available at Thingiverse.com are already laid out for printing, but there are some overhangs that are going to be a problem with my printer. I added support material, but it ends up being too much support along the sides of some of the phalanges where it really isn't necessary, and will be a beast to get off. So I'm manually tweaking the finger plate a little to include support for those overhangs. Someone probably knows an easier way to configure the support material, and there may be a better slicer program out there for this sort of thing. If you know of anything, let me know. Until I learn a better way, I'll just add some little blocks to support the overhangs.

I printed out these three pieces in 3mm yellow ABS to see how my support elements worked. They are too thick and poorly placed, so I'll try again tomorrow. They do look pretty cool though. Ultimately I'm going to print most of the hand out out of 3mm Taulman Bridge nylon. This is a newly formulated nylon that resists curling much better than earlier 3d nylon blends. I'm thinking I'll use flexible PLA which I got from 3Dsupplyworld.com, for the joint material, but I'm not completely set on that yet. Nylon is pretty flexible and I may be able to tweak the filament, density, and wall thicknesses enough to use nylon throughout.

Flexy-Hand #Abstract2Actual: 24:20 and counting (including Jeff's design time)

RSS Feed

RSS Feed