The Prusa i3 upgrade is still not complete. I have the dual hot ends, but haven't built the extruders. I do need to get that done because I want a one printer that uses 3mm filament.

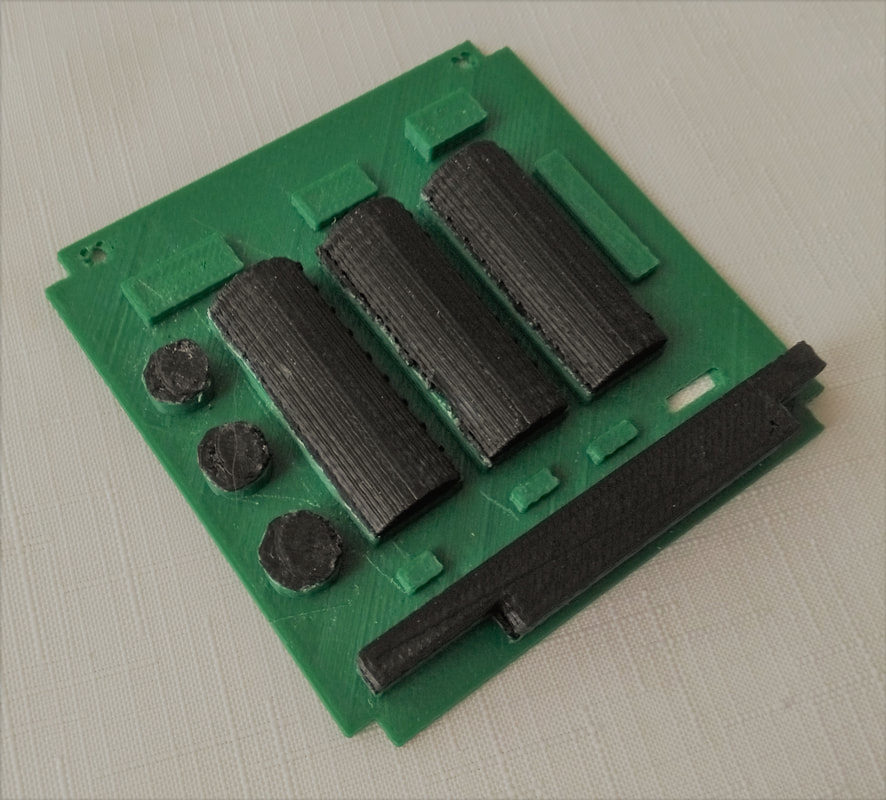

I also overhauled the old Airwolf v5.5, which involved replacing the Gen6 motherboard with a RAMPS4.4, adding an LCD display controller, replacing the 3mm Wades Extruder and hot end with a 1.75 Bowden extruder and Phaetus Dragonfly hot end. The Airwolf prints better than ever.

I also bought a Creality CR30 Printmill belt printer. It worked great for the first 30 days or so, then something got out of whack with the alignment and I'm having trouble getting parts to adhere to the bed. I'll have to do some research to figure out how to fix that. Now, on to the NYOPG.

The idea came up because Sonya, my wife, wanted to have a Halloween costume party and she decided to dress as Flo from the Progressive insurance commercials. With that costume in mind, I searched online for images of the famed prop. The only one I could find was a tiny thumbnail sized image, but it gave me enough to go on.

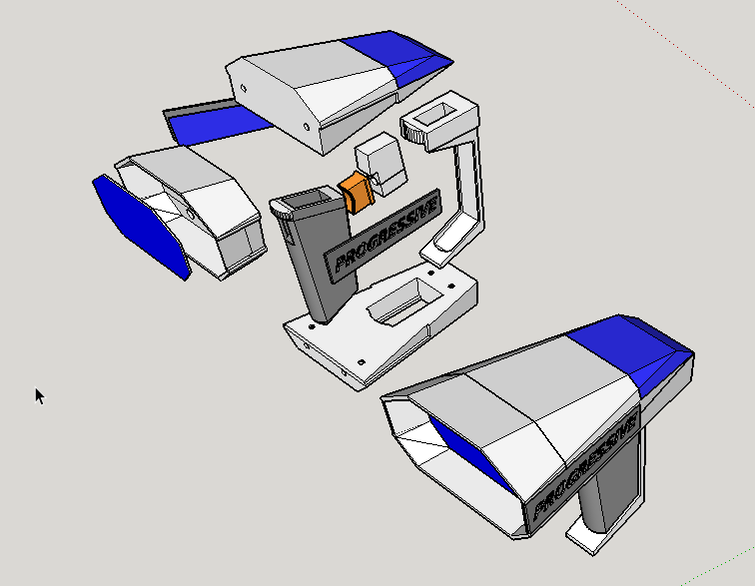

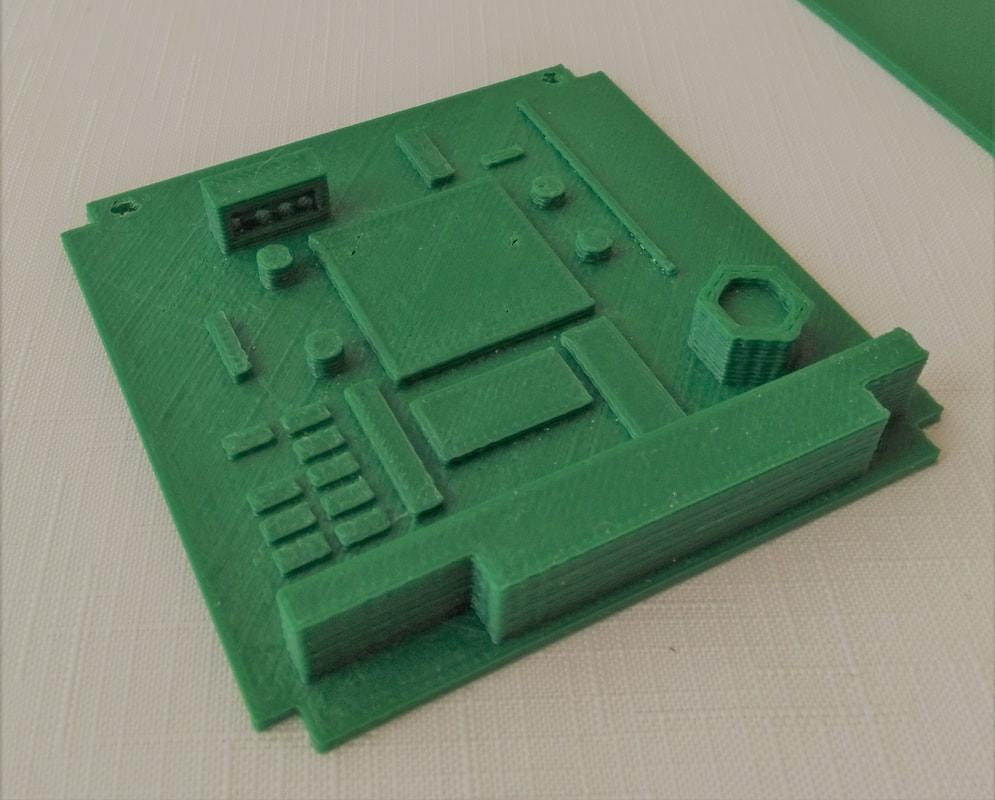

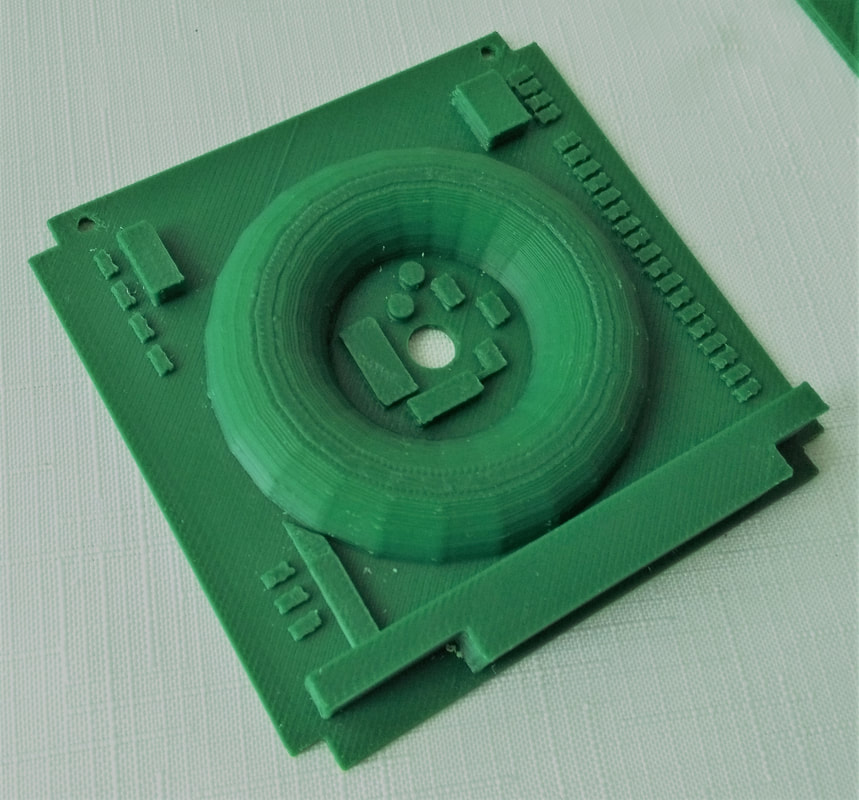

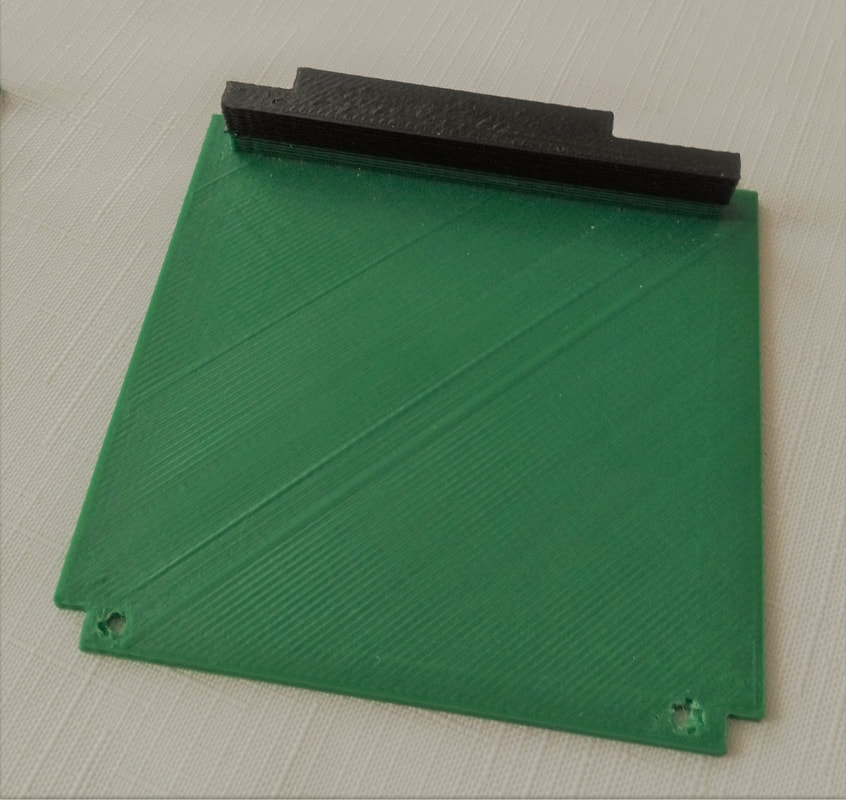

I went to work in Sketchup, first building a monolithic model. I decided I wanted the trigger to be functional so that you could squeeze it and when you release it, it would spring back into place. I had to break the monolithic model into parts so that I could come up with such a functional trigger. I separated the pistol grip from the body at first, then decided I could split the body in two parts, drop the pistol grip into the lower half, install the trigger, and screw the top half on to hold everything together. The pistol grip needed a trigger cavity, so I carved that out, then separated the trigger as an individual part. To capture the spring, I designed a block with a hole in it that sat down in the back of the trigger cavity. I sliced it all in Slic3r and sent everything to my Airwolf 5.56 printer. Printing time was just over 16 hours for all the parts.

When I went to assemble everything, I found that there was no way to install the trigger spring. I ended up cutting the block in half along the spring hole so that I could install the trigger, push it forward, insert the lower block, insert the spring, and then put the upper block in to capture the spring, which worked really well. with the trial and error, assembly time was just over an hour. I decided to paint it to match the web image, and I really didn't like how that turned out. The paint had a tendency to run along the layer lines and, even though I masked everything off, it looked rather sloppy. The other issue I had was that I didn't have the "Progressive" logo on the side.

I went back to the model and scaled it down 15% because the original seemed obnoxiously large. Then I separated the parts even further so that I could print it in the four colors I needed. I ended up with 14 parts for the final iteration which can be screwed and/or glued together. The total design time was 11 hours, 43 minutes.

I decided to print half of the new design on my X3REX modified Prusa i3 and the other half on the Airwolf 5.56 Print time on the X3REX was 8:16 for all of the white components and the Airwolf ran for 6:23 printing the color parts. This assembly took a lot more time, about 3 hours and a lot more glue, but it turned out pretty good. I wouldn't call it commercial quality, but definitely a good costume prop.

The design is posted on Thingiverse, however I have trouble opening the page there. Let me know if you have trouble with the link and I'll post another way.

RSS Feed

RSS Feed