I'd read quite a bit about Cura, and have been wanting to try it out for quite a while, but I just never had time to mess with it.

Let me just say that I love Cura. I've been using it for a few months now, and the more I use it, the more I wonder why it took me so long to come around to it..

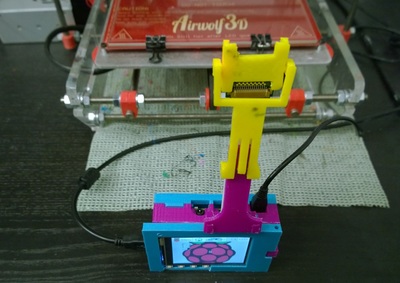

Starting out was not all sunshine and roses. First of all, none of my printers are popular commercial off the shelf printers. Although my Airwolf3D v5.5 was commercially available, it isn't popular enough to have the configuration files readily available for the slicers. My other two printers are custom builds, and so their configurations are also not publicly known.

The frist hurdle I had to overcome is that Cura couldn't understand where my print bed center was. With Slic3r v1.0, you can enter not only the bed size in the printer settings, but there is also a 'Print Center' value that you can also enter. This enables the Slicer to account for the extruder home position to be somewhere outside the print bed. Cura does not have any such setting, so I just couldn't get the prints to consistently stay within the confines of the bed. I searched and searched but couldn't find anyone who had a simple solution to this problem. I wound up working around the problem by redefining the print bed size in the machine settings so that it was original bed size plus 2X the distance that my extruder home position was from X0 and Y0 (near left corner of the print bed). This worked OK, but I had to be really careful when arranging parts in Cura to not exceed the actual bed area.

After a couple of months of this, it got really annoying, so I started searching online again for a solution. I stumbled on this solution on the Ultimaker Community website. To sum it up, you add a couple of lines to the start-gcode that moves the extruder to the front left corner of the print bed, then send a command that defines this is the new X,Y home position.

The start-gcode that I'm using on X3REX, my customized Prusa i3, is shown below:

M107; Fan off

;M190 S{print_bed_temperature} ;If you want to wait for the bed to come to temp

G21 ;set units to milimeters

G90 ;use absolute coordinates

M82; use absolute distances for extrusion

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstop

;#############################################################

;The line below moves the extruder up enough to clear the bed leveling screws

;#############################################################

G1 Z5 ; move Z up 5 because to clear the bed leveling screw on next move

M109 S{print_temperature} ;wait for extruder to come to temp

G1 F200 E3 ;extrude 3mm of feed stock

;##############################################################

;The 2 lines below are the lines that offset mechanical home to the correct starting position

;##############################################################

G1 X57.6 Y30.5 ; Move to front left corner of print bed to offset the print head

; 57.6 mm in the X axis and 30.5 mm in the Y axis from its mechanical home

G92 X0 Y0 E0; Set this coordinate to X0, Y0, Extruder0

G28 Z ; home Z, bring it back down to the bed surface to start printing

;Put printing message on LCD screen

M117 Printing...

Cura is a really nice piece of software. A couple of things I love about it are the control you have over support material, because you can have greater or lesser adhesion with the part depending on your needs. I also like the "Cut off object bottom" that lets you essentially sink the part below the bed surface so that you can start your print with a greater surface area if necessary. The visual representation of your part on the bed is really nice. And I like how it calculates build time and media consumption right on the screen.

RSS Feed

RSS Feed