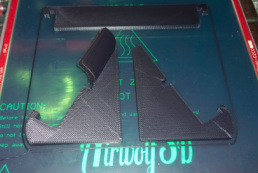

Phone stand parts, still hot on the press

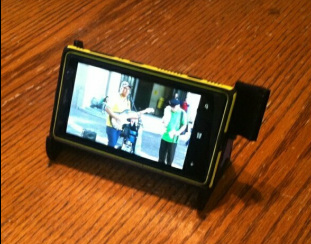

Phone stand parts, still hot on the press I have a Nokia Lumia 1020, a Windows phone that I like to watch videos on. There are two small problems I have doing this. First, the phone will not stand up on its own, and won't stay standing if I lean it against something. Second, the speaker is on the side of the phone, which means, if I do manage to get it to stand up, I don't get the full sound because it is directed 90 degrees away from me. I'm going to build a three piece stand with two uprights and a brace to hold them. the upright on the right side has a curved piece to channel the sound around to the front.

It took me 36 minutes to design the stand in Google SketchUp. It took another 18 minutes to prepare the printer, and slice the file. Part of the printer prep time was switching to 3mm black ABS plastic from the flexible PLA that I used for the finger joints on the prosthetic hand project. Printing all three parts took 2:19 on my Airwolf3d v5.5 printer. After 7 minutes of cooling, i popped the parts together and found a couple of problems.

The brace didn't fit as snugly as I expected, so the uprights would wobble around and the phone could fall out of it. Also, I didn't take into account that the lens on the back of this phone protrudes another 3mm from the back of the case, so instead of sitting all the way back against the brace, the top tilted forward, which put the speaker forward of the sound channel, rendering that feature useless. Finally, the uprights were just at the edges of the phone, which left no room for error when placing the phone in the stand. It only took two minutes to figure this out.

All of these problems could be resolved by making a few tweaks to the back brace. The uprights could be used as they already were. I went back to SketchUp and made corrections to the back brace, which took 11 minutes. Prepping the printer and slicing the .stl file only took 3 minutes, since there was no filament change-out required, and I started heating the printer when I sat down to redesign the brace. Reprinting the brace took 44 minutes. It only took 2 minutes to cool the part and get it off of the printbed because I shut off the bed heater during the last 5 minutes of the print job. #Abstract2Actual 4:12

It took me 36 minutes to design the stand in Google SketchUp. It took another 18 minutes to prepare the printer, and slice the file. Part of the printer prep time was switching to 3mm black ABS plastic from the flexible PLA that I used for the finger joints on the prosthetic hand project. Printing all three parts took 2:19 on my Airwolf3d v5.5 printer. After 7 minutes of cooling, i popped the parts together and found a couple of problems.

The brace didn't fit as snugly as I expected, so the uprights would wobble around and the phone could fall out of it. Also, I didn't take into account that the lens on the back of this phone protrudes another 3mm from the back of the case, so instead of sitting all the way back against the brace, the top tilted forward, which put the speaker forward of the sound channel, rendering that feature useless. Finally, the uprights were just at the edges of the phone, which left no room for error when placing the phone in the stand. It only took two minutes to figure this out.

All of these problems could be resolved by making a few tweaks to the back brace. The uprights could be used as they already were. I went back to SketchUp and made corrections to the back brace, which took 11 minutes. Prepping the printer and slicing the .stl file only took 3 minutes, since there was no filament change-out required, and I started heating the printer when I sat down to redesign the brace. Reprinting the brace took 44 minutes. It only took 2 minutes to cool the part and get it off of the printbed because I shut off the bed heater during the last 5 minutes of the print job. #Abstract2Actual 4:12

RSS Feed

RSS Feed